Plating Equipment introduction

It is a method of plating products in a continuous roll. The advantages of this production method are that it can achieve stable quality at low cost, and the design of the production line allows various processes to be carried out depending on the shape of the product.

| Specification: |

Rolled product (Width: ~ 90 mm.(Max), Thickness: ~ 0.64 mm.(Max) ※ This number changes depending on the material and shape of the product. Material: Fe material (42 material, etc.), Cu base material (copper, brass, bronze, etc.) |

| Planting Type: |

Full surface tin plating (primer = Cu, Ni), partial tin plating (primer = Ni) ※ This plating can include a heating step to melt tin.Copper plating: Full copper plating Nickel plating: Full nickel plating (primer = Cu or Ni) |

The product is hung on the hook of a container called a rack and plated while shaking in the plating solution. It supports the rods, frames, and plates used in transformer units, electric train fuses.

| Specification: |

For products that are easily deformed Material: Fe material (SUS material, 42 material, etc.) Cu material |

| Planting Type: |

Silver plating: full surface Ag plating (primer plating = Cu, Ni) Tin plating: full surface Sn plating (primer plating = Ni, Cu) Nickel plating: full surface Ni plating (primer plating = Cu) Copper plating: full surface Cu plating |

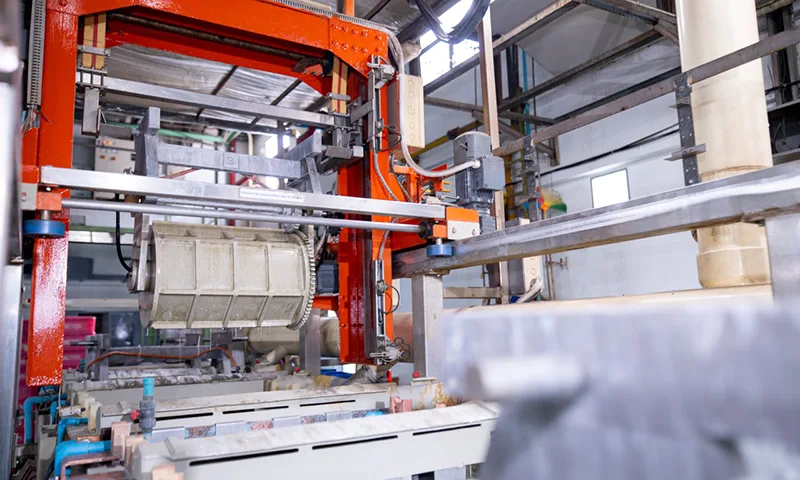

The product is placed in a container called a barrel and plated by a plating method while rotating in the plating solution. This plating solution supports connectors, frames, screws, covers, switches, and relay parts used in TVs, PCs, and mobile phones.

| Specification: |

A shape that fits into the container. The size does not pass through the gap. ※ Except for products with severe deformation Material: Fe material (SUS material, 42 material, etc.) Cu material |

| Planting Type: |

Silver plating: Full surface Ag plating (primer plating = Cu,Ni) Tin plating: Full surface Sn plating (primer plating = Ni, Cu) Nickel plating: Full surface Ni plating (primer plating = Cu) Copper plating: Full Cu plating |

It is a method of plating products in a continuous roll. The advantages of this production method are that it can achieve stable quality at low cost, and the design of the production line allows various processes to be carried out depending on the shape of the product.

| Specification: |

Rolled product (Width: ~ 90 mm.(Max), Thickness: ~ 0.64 mm.(Max) ※ This number changes depending on the material and shape of the product. Material: Fe material (42 material, etc.), Cu base material (copper, brass, bronze, etc.) |

| Planting Type: |

Full surface tin plating (primer = Cu, Ni), partial tin plating (primer = Ni) ※ This plating can include a heating step to melt tin.Copper plating: Full copper plating Nickel plating: Full nickel plating (primer = Cu or Ni) |

The product is hung on the hook of a container called a rack and plated while shaking in the plating solution. It supports the rods, frames, and plates used in transformer units, electric train fuses.

| Specification: |

For products that are easily deformed Material: Fe material (SUS material, 42 material, etc.) Cu material |

| Planting Type: |

Silver plating: full surface Ag plating (primer plating = Cu, Ni) Tin plating: full surface Sn plating (primer plating = Ni, Cu) Nickel plating: full surface Ni plating (primer plating = Cu) Copper plating: full surface Cu plating |

The product is placed in a container called a barrel and plated by a plating method while rotating in the plating solution. This plating solution supports connectors, frames, screws, covers, switches, and relay parts used in TVs, PCs, and mobile phones.

| Specification: |

A shape that fits into the container. The size does not pass through the gap. ※ Except for products with severe deformation Material: Fe material (SUS material, 42 material, etc.) Cu material |

| Planting Type: |

Silver plating: Full surface Ag plating (primer plating = Cu,Ni) Tin plating: Full surface Sn plating (primer plating = Ni, Cu) Nickel plating: Full surface Ni plating (primer plating = Cu) Copper plating: Full Cu plating |

Heat treatment is a crucial process used to alter the physical and sometimes chemical properties of a metal. it can significantly affect the properties of metals, making them suitable for specific applications as.

| Annealing: |

Soften metal, improve ductility, and relieve internal stresses. |

| Quenching: |

Harden a metal. |

| Tempering: |

Reduce brittleness following quenching. |

| Normalizing : |

Refine the grain structure and improve mechanical properties. |

| Stress relieving : |

Reduce residual stresses in metal caused by processes such as welding or machining. |

| Aging : |

Enhance strength and hardness over time or through heat application in certain alloys. |

The grinding process is a machining operation used to refine (Clear stamping burr) and smooth surfaces, often as prepare of a part material to have expected dimension or surface. This process uses an abrasive material, typically a rotating grinding pot, to remove small amounts of material from a workpiece

Heat treatment is a crucial process used to alter the physical and sometimes chemical properties of a metal. it can significantly affect the properties of metals, making them suitable for specific applications as.

| Annealing: |

Soften metal, improve ductility, and relieve internal stresses. |

| Quenching: |

Harden a metal. |

| Tempering: |

Reduce brittleness following quenching. |

| Normalizing : |

Refine the grain structure and improve mechanical properties. |

| Stress relieving : |

Reduce residual stresses in metal caused by processes such as welding or machining. |

| Aging : |

Enhance strength and hardness over time or through heat application in certain alloys |

The grinding process is a machining operation used to refine (Clear stamping burr) and smooth surfaces, often as prepare of a part material to have expected dimension or surface. This process uses an abrasive material, typically a rotating grinding pot, to remove small amounts of material from a workpiece